| شاسی کف | تیرآهنهایی با نمره ۱۴، ۱۶ و ۱۸، ذوبآهن، قوطیهای سنگین دور کلاف ۸۰ * ۸۰ |

| اسکلت کانکس | پروفیلهای ۴۰*۴۰، ۶۰*۴۰، ۸۰*۴۰ سنگین با ضخامت حدودی ۵.۱ میلیمتر. این محصولات ضدزنگ هستند و با ضخامتی کم روی کل سازه اجرا میشوند. |

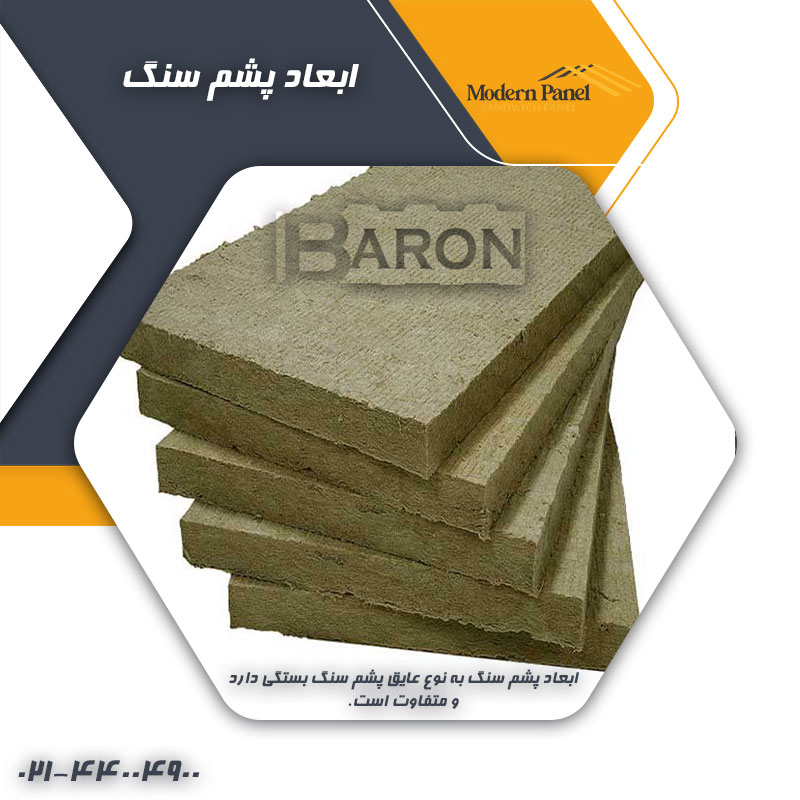

| پوشش سطوح جانبی | پانلهای ساندویچی سهلایه. لایههای رویی از جنس فولاد (گالوانیزه، آلوزینک یا آلومینیوم) هستند. فوم عایق میانی نیز میتواند پلی اورتان، پلیاستایرن، پشم سنگ یا… باشد. |

| درب | جنس درب این کانکسها متغیر است. اما به طور معمول از UPVC ساخته میشود. |

| شیشهها | معمولاً دوجداره هستند تا خاصیت عایق بودن پانلها حفظ شود. |

| تخته کف | تختههایی چندلایه که روکش دارند. این تختهها معمولاً ضد خش هستند. |

| کفپوش | میتواند جنسهای متفاوتی داشته باشد. اما بهتر است PVC یا پارکت در آن اجرا شود. |

| سیستم روشنایی | بسته به سفارش مشتری متغیر است. اما به طور معمول از لامپهای مهتابی استفاده میشود. سیمکشیهای آن نیز توکار هستند. |

| رنگ | میتواند از تمام رال رنگهای ساندویچ پانل باشد. حتی میتوان از پانلهای طرحدار در ساخت این کانکسها استفاده کرد. |

| ابعاد | ۲.۴*۴ متر، ۲.۴*۶ متر، ۳*۸ متر، ۳*۱۲ متر، ۳.۵*۱۲ متر |

| ضخامت | بسته به سفارش مشتری متنوع است. در کانکسهایی مانند سردخانهها یا نیروگاهها از بیشترین ضخامت استفاده میشود. |

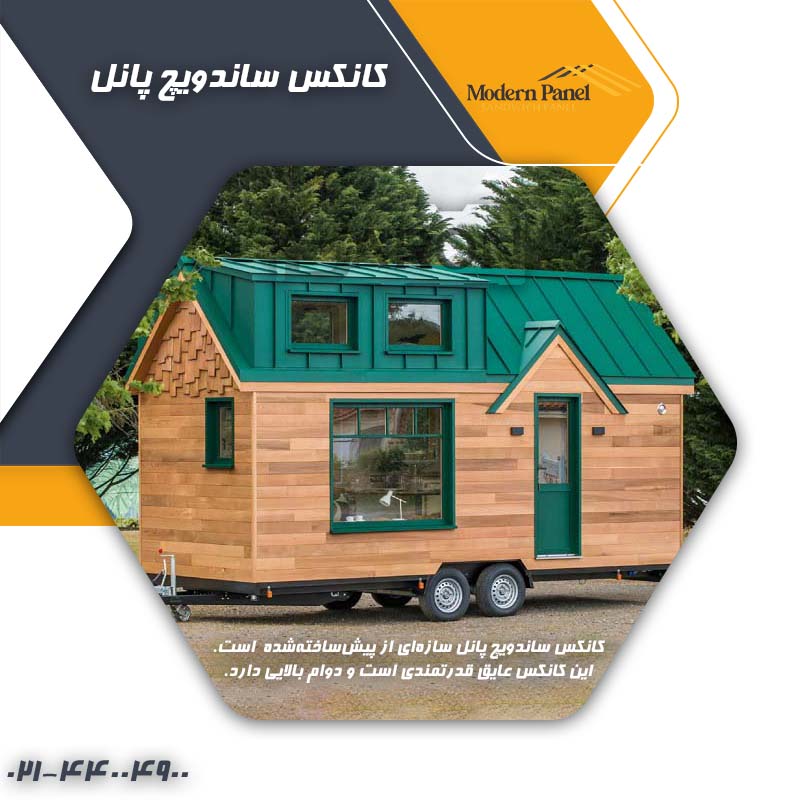

معرفی کانکس ساندویچ پانل

کانکس سازهای ازپیشساختهشده است. این سازه قابل حمل است. به طوری که در کارگاه تولید و ساخته شده و بعد به مکان مورد نظر منتقل میشود. از این رو استفاده از چنین سازهای در محلهایی که امکان ساختوساز نیست، گزینههای ایده آل محسوب میشود.

کانکسها با متریال مختلفی ساخته میشوند. اما نوعی که اینجا مد نظر ما است، با ساندویچ پانل سقفی و دیواری ساخته میشود و جزو مقاومترین کانکسها است. چنین کانکسی یک عایق پایدار و قوی است در برابر عوامل محیطی مانند باد، باران، دمای کم یا زیاد، حرارت، صوت و… .

اما ویژگی دیگر کانکس ساندویچ پانل میزان تنوع و انعطافی است که این پانلها دارند. برای مثال میتوانید کانکسها را در انواع رنگها داشته باشید تا با محیط هماهنگ باشد. حتی میتواند طرحهای متنوعی را هم برای دیوارها یا سقف سفارش دهید.

کانکس ساندویچ پانل ثابت و متحرک

کانکسها به دو نوع اصلی ثابت و متحرک تقسیم میشوند. کانکس متحرک در قسمت زیرین خود دارای چرخ است. بنابراین بهراحتی میتوان آنها را حرکت داد. اما کانکس ثابت این چرخها را ندارد.

البته کانکس ثابت را هم میتوان با تجهیزات و ماشینآلات مناسب جابهجا کرد. اما این کار به راحتی جابهجایی کانکسهای متحرک نیست. به همین دلیل است که از این نوع کانکسها برای مکانهایی استفاده میشود که قرار است مدتی طولانی ثابت باشند.

کاربرد کانکسهای ساندویچ پانل

ساخت کانکس با ساندویچ پانل با هدف شبیهسازی مکانهای مختلف انجام میشود. اما بیشترین کاربرد این کانکسها عبارت است از:

- واحدهای مسکونی و اداری

- واحد نگهبانی

- کارگاه

- ویلا

- سردخانه

- سرویس بهداشتی

- درمانگاه و واحد اورژانس

- نمازخانه

- اسکان موقت

- پشتبند تریلر

کانکس ساندویچ پانل به چه دستههایی تقسیم میشود؟

کانکسها از نظر تجاری و از لحاظ کاربردی که دارند، به دستههای مختلفی تقسیم میشوند؛ از جمله:

- ساده

- مسکونی

- دفتری

- صنعتی

- سیار

- ساندویچی با ابعاد بزرگ

- ساندویچی با ابعاد کوچک

مدرن پانل به عنوان تأمینکننده و عرضهکننده انواع ساندویچ پانل دیواری و سقفی و مصالح ساختمانی مدرن، آماده است تا انواع این کانکسها را با توجه به نیاز و سفارش مشتری تولید کند.

باکیفیت ترین پوشش سقف و دیوار سازه را سفارش دهید.

جهت مشاوره پیش از خرید با مشاو فروش مدرن پانل تماس حاصل نمایید.

متریال استفادهشده در کانکسهای ساندویچ پانل

گفتیم که در ساخت دیوارها و سقف این کانکسها از ساندویچ پانل استفاده میشود. اما این تنها متریالی نیست که این سازه را تشکیل میدهد. کل مصالحی را که در ساخت کانکس با ساندویچ پانل استفاده میشوند، در جدول زیر مشاهده میکنید.

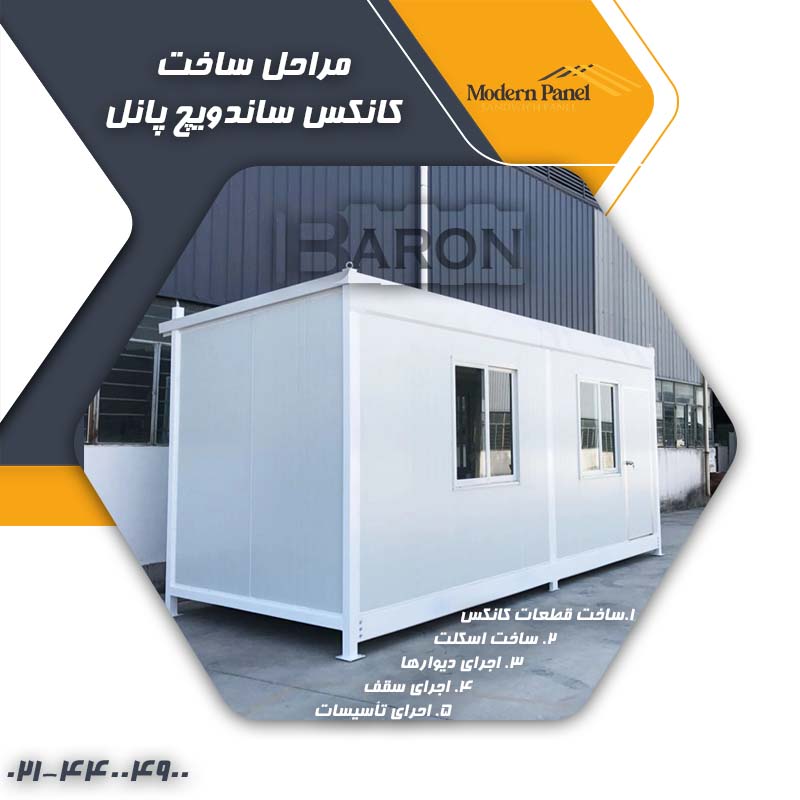

مراحل ساخت کانکس با ساندویچ پانل

طراحی و تولید کانکس ساندویچ پانل یک سری مراحل کلی دارد که برای همه کانکسها مشابه هستند. این مراحل را در ادامه مرور میکنیم.

1. طراحی و ساخت قطعات کانکسها

در اولین قدم، مشخصات قطعات مختلف کانکس، از جمله ساندویچ پانل دیواری و سقفی، بر اساس نیاز مشتری تعیین میشوند. سپس کانکس مورد انتظار در نرمافزارهای طراحی دوبعدی یا سهبعدی طراحی میشود.

2. ساخت اسکلت

اسکلت اصلی این کانکسها شامل شاسی و استراکچر است. این دو بخش با ترکیب مصالحی از جمله تیرآهن و پروفیلها ساخته میشوند. برای محکم کردن آنها نیز از قید استفاده میشود.

3. اجرای دیوارها

تا اینجا کار، اسکلت اصلی کانکس ساخته شده است. پس حالا باید دیوارکشیها انجام شود. برای این کار ساندویچ پانلها به کمک پیچهای سرمته گالوانیزه روی اسکلت کانکس اجرا میشوند. بعد روی آنها یک روکش کشیده میشود.

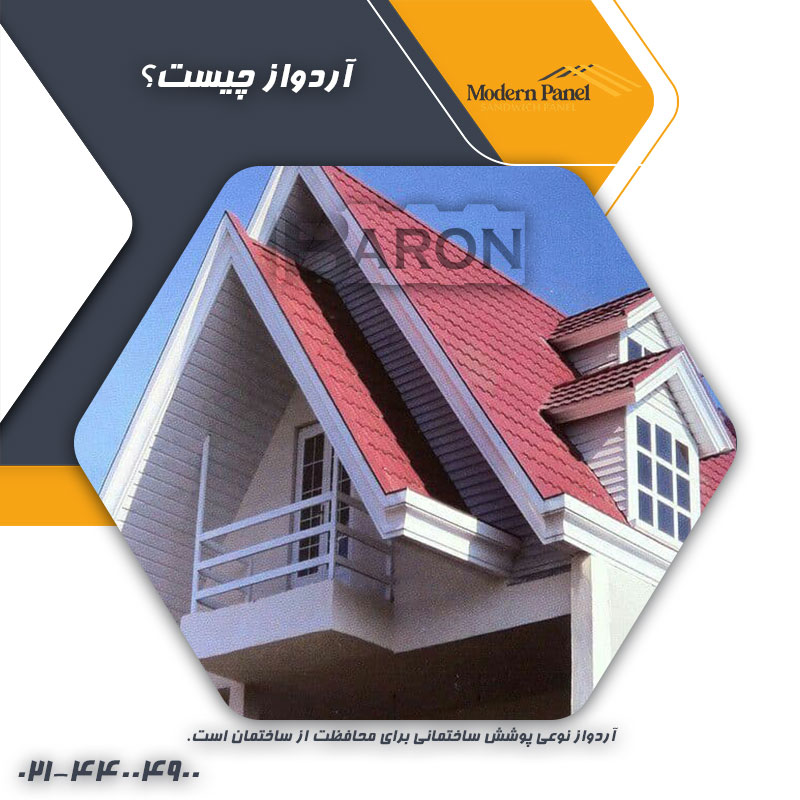

4. اجرای سقف

سقف این کانکسها هم از ساندویچ پانل است. سقف هم یک اسکت دارد که روی زیرسازی دیوار قرار گرفته است. پس پانلها روی اسکلت سقف نصب میشوند. در این مرحله فلاشینگها و آبروها هم نصب میشوند.

بعد از این که پانلها نصب شدند، باید با فوم پلیاورتان یا چسب سیلیکونی مایع درزگیری شوند. با این کار راه نفوذی برای آب، گرد و خاک یا رطوبت باقی نمیماند.

5. اجرای سایر تجهیزات و تأسیسات

در آخر نوبت به نصب و اجرای تأسیسات میرسد. از کفپوشها و سیستم روشنایی گرفته تا نصب در، پنجره، پارتیشنهای داخلی و…

آموزش ساخت کانکس با ساندویچ پانل

با یادگیری مراحل آموزش ساخت کانکس با ساندویچ پانل میتوانید طرحهای خلاقانه را ایجاد کنید. علاوه بر آن یادگیری ساخت یک مهارت به شمار میآید و برای راهاندازی کسب و کار مفید خواهد بود. با وجود این که ساخت کانکس با ساندویچ پانل روشی آسان است، اما برای انجام صحیح آن نیاز به آموزش و یادگیری اصول و نکات مربوطه است. با تمرین و کسب تجربه میتوانید انواع کانکس را ایجاد کنید. با یادگیری این مراحل میتوانید از ساندویچ پانلها در طرح و رنگهای مختلف استفاده کرده و کانکسی مطابق با سلیقه شخصی خود ایجاد کنید.

ویژگیهای کانکس ساندویچ پانل

کانکس ساندویچ پانل مقاومتر از کانکسهای سنتی است. اما این سازهها مزایای دیگری هم دارند. ازجمله:

- عایق قوی در برابر دما، حرارت، رطوبت و صدا

- وزن کم

- مقاومت بالا

- ضد زلزله بودن

- جذابیت بصری و امکان ساخت در رنگهای مختلف

قیمت کانکس ساندویچ پانلی

قیمت این محصولات بسیار متغیر است. برای تعیین تعرفهها اول باید کارایی سازه مشخص شود. سپس متریال مناسب برای کاربرد مد نظر انتخاب میشود. در واقع این متریال و ابعاد کانکس است که در قیمتها تعیینکننده است.

برای مثال کانکسی که در پانلهای آن از فوم پلیاورتان استفاده شده، معمولاً قیمت بالاتری دارد. یا کانکسهای که پانل آنها ضخامت کمتری دارد، ارزانتر هستند. همینطور متراژهای مختلف نیز تعرفههای گوناگون دارند. اگر برای سفارش کانکس نیاز به مشاوره دارید یا مایلید تعرفهها را بدانید، پیشنهاد میکنیم که با شماره 09122949891 تماس بگیرید.

پرسشهای پرتکرار